Metalltec-Tools

Rehm Synergic.ARC 304 Gas-cooled

Rehm Synergic.ARC 304 Gas-cooled

Couldn't load pickup availability

THE SYNERGIC.ARC SERIES: MIG/MAG HIGH-PERFORMANCE MACHINES – MAXIMUM ROBUST AND ENERGY EFFICIENT

The SYNERGIC.ARC 304 to 504 offer above-average resilience in continuous operation at a high level. With continuous outputs of 270 A, 330 A and 400 A, these welding machines are among the front runners in terms of deposition rate. The 4-roller wire drive is robust and reliable. The chassis is equipped with large wheels (160 mm at the front, 250 mm at the rear) and designed for transporting 50 l gas cylinders. An integrated ramp makes loading easier and protects the operator's back, which reduces accidents at work. The entire control panel is durable and designed for tough use. The display is protected by an impact-resistant 3 mm protective screen and can also be protected from sparks and welding spatter by a cover. The control knob is also impact-protected and particularly robust thanks to its special mechanical design. By connecting the intermediate hose package at the front, the range of the feed case can be increased by approx. 1.5 m.

The FOCUS.ARC welding process offers a higher performance than the spray arc in conventional welding with the SYNERGIC.ARC 304 to 504. An efficient welding result is achieved by using a short and powerful arc. Root and flank seams are reliably detected and undercuts are reduced.

The SYNERGIC.ARC 251-351 are the all-rounders for industry and trade with thin and medium sheet thicknesses. The welding parameters can be easily set thanks to the synergy characteristics created by REHM, which makes the SYNERGIC.ARC easy to use, even for beginners. Pre-programmed settings are available for different materials such as Fe, CrNi, Alu and CuSi3. Thanks to the REHM SDI technology and the arc length controller, the arc can be optimally adjusted, even for delicate applications.

Thanks to its small dimensions, the SYNERGIC.ARC 251-351 fits easily under any workbench and is therefore an ideal workshop machine. The 4-roll wire drive is robust and reliable. The chassis is specially designed for 20 l gas cylinders. The SYNERGIC.ARC is equipped with 2 operating variants as standard.

The SIRIUS technology shows its strengths with the SYNERGIC.ARC by combining two operating options in one machine. In addition, the 7-inch display offers a clear representation and allows a good overview even from a distance.

OPERATION 1: Based on stepless devices

OPERATION 2: Based on stepped devices

SYNERGIC.ARC and SIRIUS – It couldn't be simpler

The SYNERGIC.ARC is the ideal choice if you want to weld better, safer and more efficiently. She is not only a true welder's friend, but also a reliable and effective worker rolled into one. With its simple operation and the proven digital operating system SIRIUS, the SYNERGIC.ARC is simply better.

The benchmark in the operation of welding machines

SIRIUS is an innovative digital operating system that simplifies the operation of complex digitally controlled processes. It offers a graphically dynamic and transparent visualization as well as assist functions and enjoys the highest level of user acceptance. With SIRIUS, complex things are made simple. The new, digitally controlled SYNERGIC.ARC machine offers a variety of optimization options that must be used in modern production to increase competitiveness. The SYNERGIC.ARC combines the finest welding machine technology with maximum ease of use. The innovative operating system SIRIUS is the heart and simplifies complex relationships for the user and makes them comprehensible. The essential elements of operation.

SIRIUS is an innovative digital operating system that simplifies the operation of complex digitally controlled processes. It offers a graphically dynamic and transparent visualization as well as assist functions and enjoys the highest level of user acceptance. With SIRIUS, complex things are made simple. The new, digitally controlled SYNERGIC.ARC machine offers a variety of optimization options that must be used in modern production to increase competitiveness. The SYNERGIC.ARC combines the finest welding machine technology with maximum ease of use. The innovative operating system SIRIUS is the heart and simplifies complex relationships for the user and makes them comprehensible. The essential elements of operation.

The SYNERGIC.ARC offers a central, high-resolution display with an optimal size of 7 inches, which shows everything at a glance in an excellent graphic representation. The display is protected by an impact-resistant 3 mm thick plastic pane and is therefore more robust than conventional displays. The SYNERGIC.ARC 304/404/504 has the Quick Choice buttons for quick and easy storage of current welding tasks. The central control element called R-Pilot allows one-handed operation, even with gloves. It is the only protruding control element and is protected from mechanical damage by side handles/plastic parts.

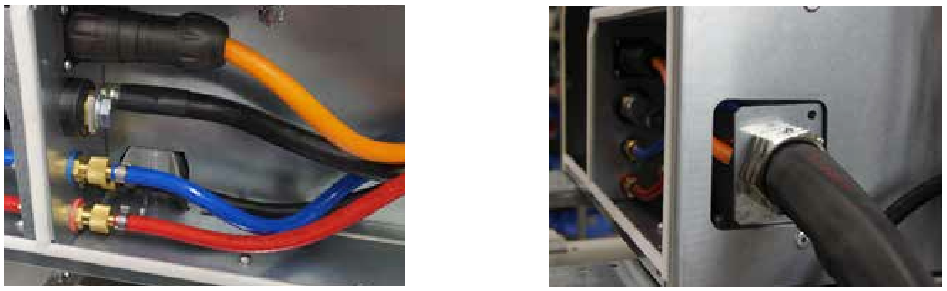

The proven inverter technology from REHM ensures ultra-fast and low-induction operation of the SYNERGIC.ARC. A powerful, digitally controlled feed motor ensures even wire feeding. All SYNERGIC.ARC devices are equipped with a 4-roller precision feed system whose conveyor rollers can be changed easily and without tools. The angled torch connection protects the hose package and the cable and at the same time ensures ideal wire routing. The intermediate hose packages of the SYNERGIC.ARC are attached to the feed case with a robust metal strain relief as standard.

Easy to move: Thanks to the robust chassis with large and smooth-running wheels, the devices are easy to maneuver and transport in the workshop or on the construction site. They are also suitable for transport with a crane or forklift (304, 404, 504).

Individually adaptable: With various options and retrofittable equipment, our welding machines can be adapted to your individual needs.

Conformity to EN 1090: The SYNERGIC.ARC displays all relevant parameters and thus meets the requirements of the standard.

Environmentally friendly: Due to its high level of efficiency, the SYNERGIC.ARC meets all the requirements of the EU directive for eco-design*. (*Directive 2009/125/EG of the European Parliament and of the Council of October 21, 2009)

- ≥85% efficiency

- ≤50W standby

- Up to 30% energy savings when welding compared to existing devices

- Up to 80% energy savings when idling, thanks to intelligent stand-by management

- Maximum duty cycle thanks to the low-loss REHM inverter

Figure 1 shows device with accessory option.

Scope of delivery (without accessory option):

- Device

With accessory option:

-Premium Set RC24/4/UD MaKa 25mm ² Drumi (burner, ground cable, pressure reducer)

- Floor attachment

- Air filter attachment

- toolbox

- Torch and hose package holder

Further accessories on request

Delivery time 4 weeks

Free Shipping

Photo: Rehm Uhingen

Accessories on request

-

torch holder

-

Air filter attachment metal mesh

-

floor attachment

-

Toolbox for compact devices

-

trolley

FAQ

What is the wear parts guarantee?

We want you to have the right consumables for your torch.

If you order wearing parts from us and you notice that they are not

fit on the burner, then there are two easy options. they send

return the items and get the right ones sent straight to you. Or you

get your money back. Complete! Simple and always guaranteed that you get the right ones

have wear parts.

May I test my item in advance?

At Metalltec-Tools you can of course test the items with us in advance.

You also get a free demonstration when you buy a device, for example

would like. Just send a message to the chat and we'll set one up

Meeting!

With which providers do we ship the items?

DHL, UPS, Hermes. With these providers, our items are sent to you as quickly as possible.

I'm not sure if this is the right article...

No problem, just write a short message in the chat.

If you want, you can of course also get one for free

Consultation. Just send the phone number in the chat. We call

you back as soon as possible!

Further questions?

Then just write a message in the chat or via Whatsapp!

We are here for you!